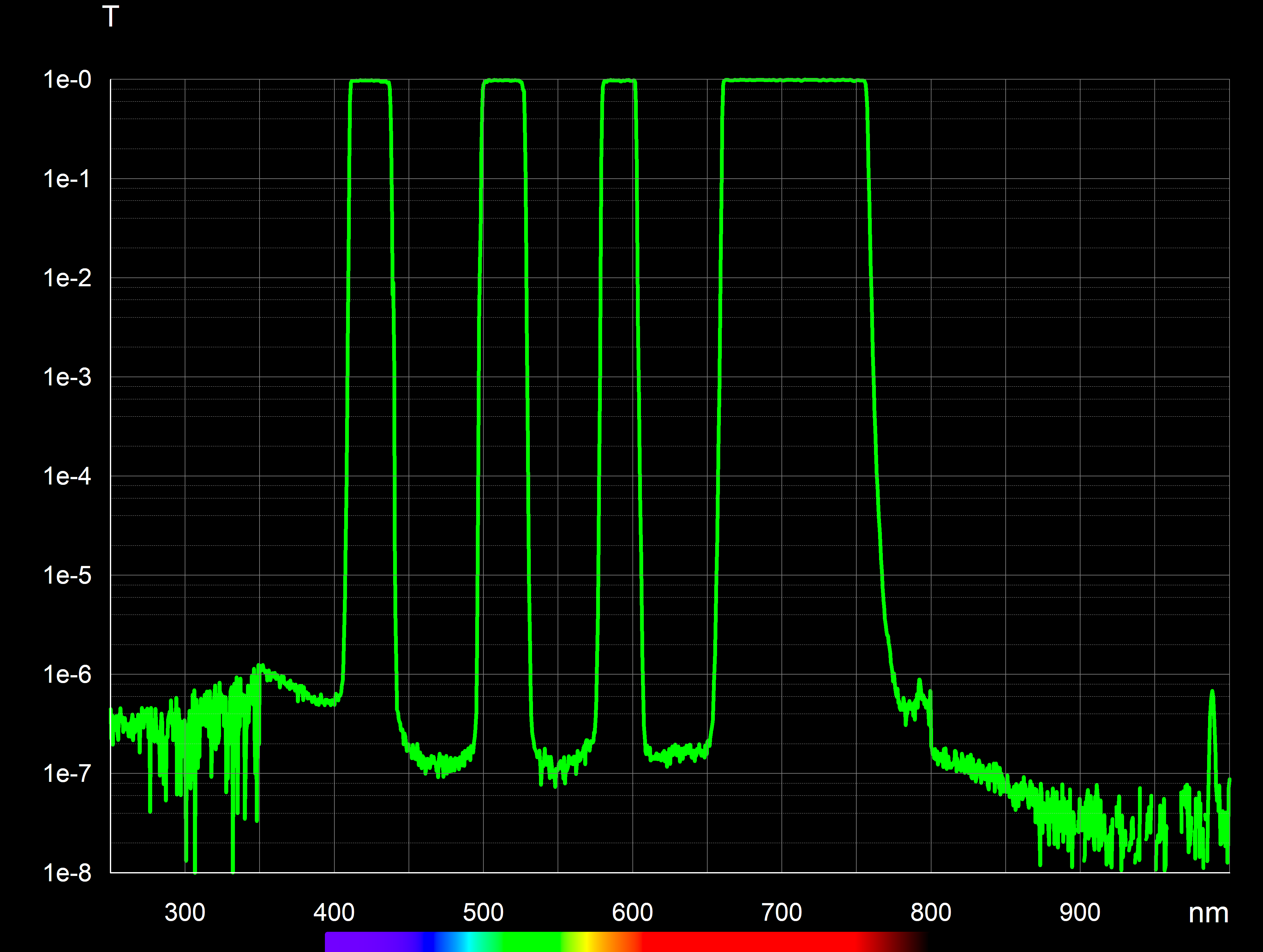

New products: Quad-band emission filter and beamsplitter

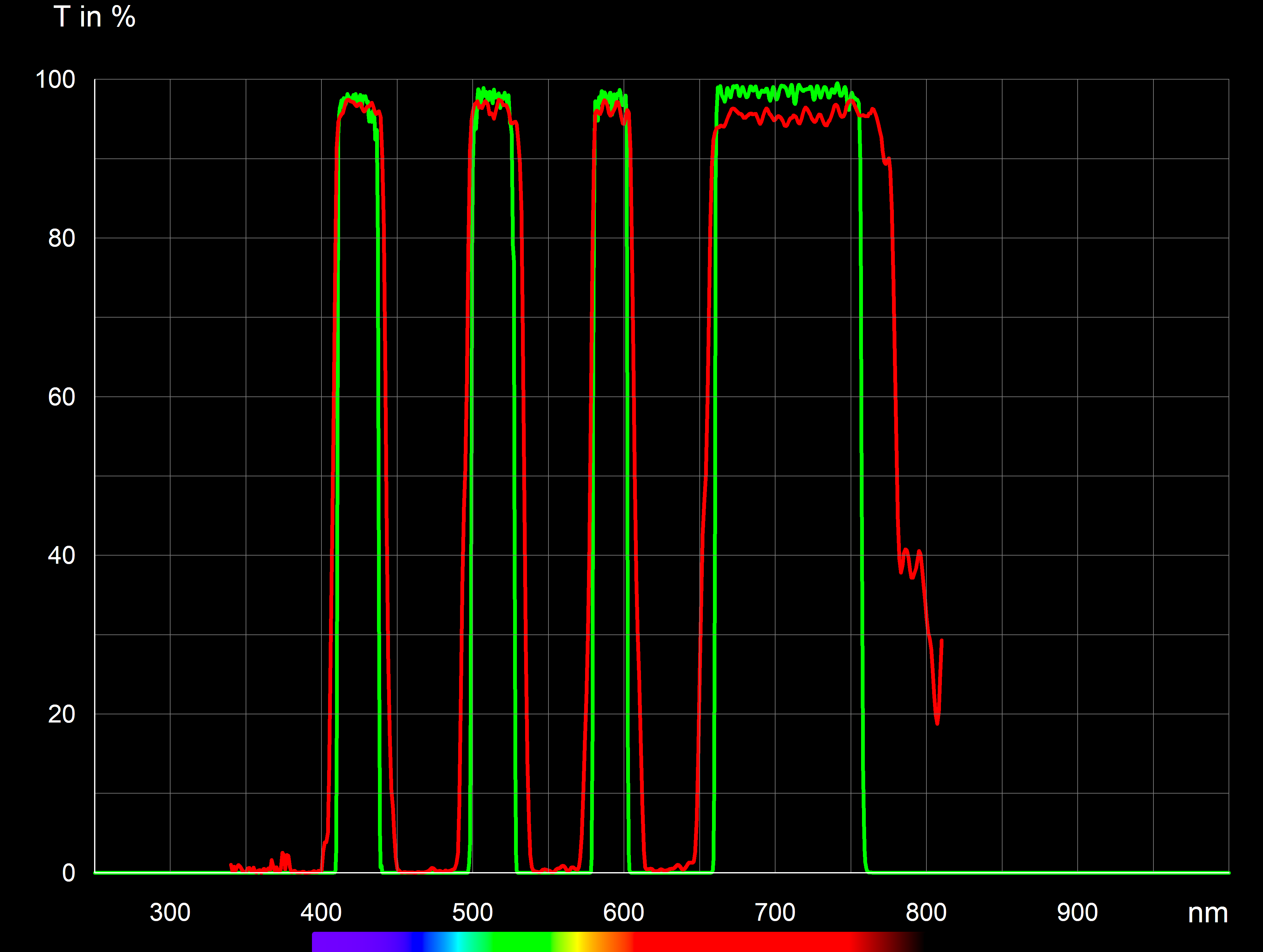

Delta Optical Thin Film now offers filters with up to four wavelength pass-bands for multi-spectral fluorescence instrumentation.

The commercial availability of Light Emitting Diodes at almost any wavelength combined with Multi-Bandpass Filters have enabled a new type of Fluorescence instrumentation. These new instruments offer ultrafast switching between different wavelengths with-out the need for moving or replaceable filter parts.

We are proud to present our newest Multi-Bandpass filter products; a quad-band emission filter and a quad-band dichroic beamsplitter.

These products are excellent examples of the kind of filters that Delta Optical Thin Film can design and manufacture for our OEM-customers.

You can read more about our Multi-Band Filters and Dichroics below.

Meet us at Photonics West 2024

We will be joining the BIOS Expo and Photonics West 2024 exhibitions from January 27th to February 1st.

This is the largets photonics event in North America and it is a great opportunity to become updated on the latest trends in optical thin film filters

We are experts in optical thin film filters and have designed and manufactured those for more than 5 decades.

We constantly challenge the technology and develop new optical filters that efficiently solve advanced requirements in close dialogue with our OEM customers.

At the BiOS and Photonics West exhibitions in the Moscone Center in San Francisco you have the chance to discuss your optical filtering needs directly with our experts.

Make sure to swing by our booth:

BiOS: January 27 and 28th, Booth 8552

Photonics West: January 30th to February 1st, Booth 3552

We are dedicated to build strong OEM partnerships, believing that working together can lead to more efficient, cost-effective solutions. So, let’s have a talk about this.

Explore Our Advanced Multi Bandpass Filters

Multi-bandpass filters are well suited for fluorescence spectroscopy instruments that need to work with multiple excitation wavelengths and/or multiple emission wavelengths.

We manufacture double, triple, and quad bandpass filters with high pass-band transmission and deep out-of-band blocking.

In combination with a range of LEDs, these filters are ideal for building fast and complex optical systems with no moving parts.

The right Notch Filter for your needs

Notch Filters are designed to selectively block specific wavelengths while maintaining high transmission of other spectral regions.

Our notch filters are fully customisable in terms of centre wavelength and bandwidth, enabling applications in a broad range of practical technologies including Raman spectroscopy, fluorescence spectroscopy, microscopy and many other applications.

Contact us to initiate a discussion where we together can find the perfect solution for your precise optical filtering requirements.

Endless possibilities with Variable Filters

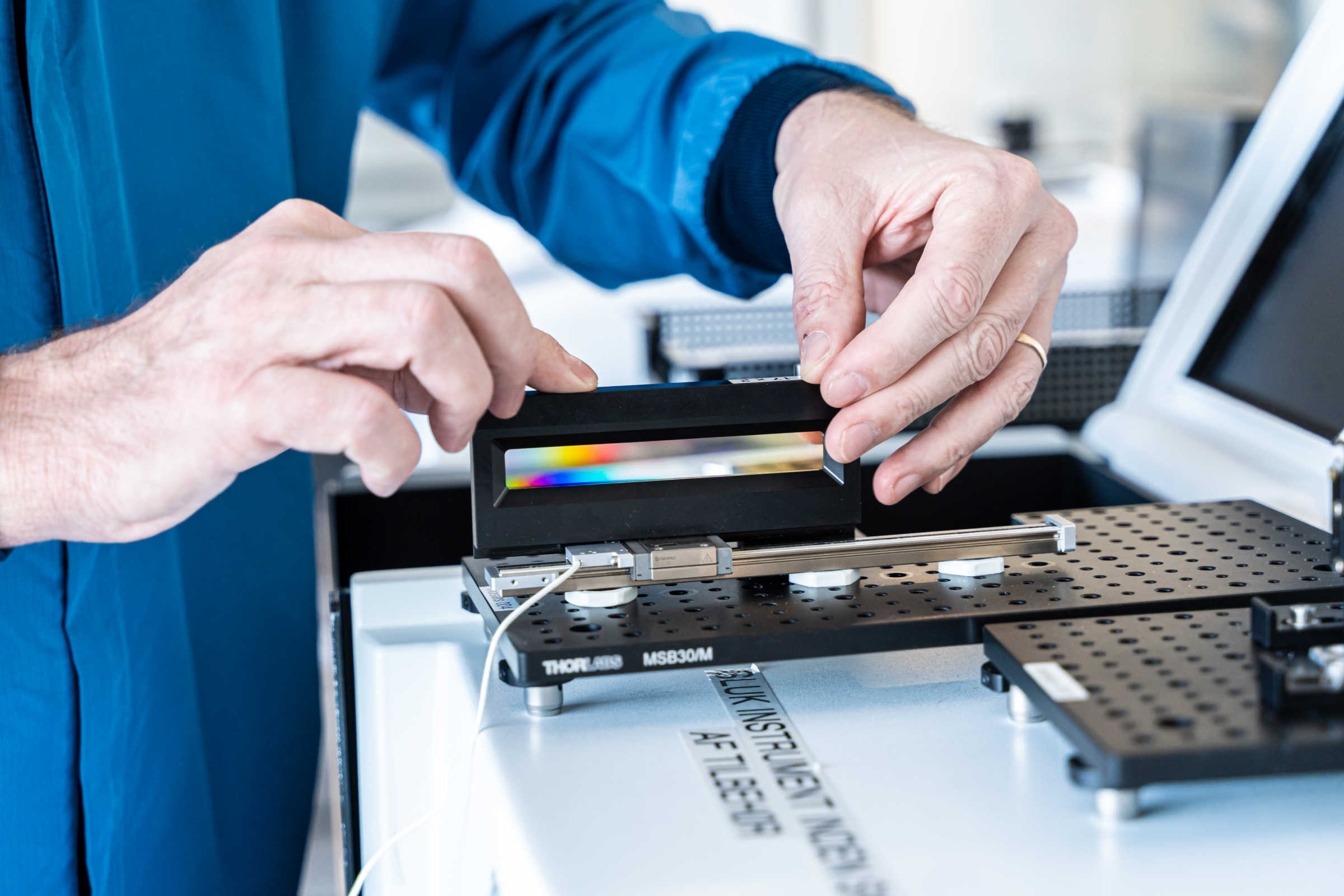

Continuously Variable Filters (CVFs) – also known as Linear Variable Filters – from Delta Optical Thin Film is wedged filters, whose spectral properties vary continuously along one dimension of the filter.

A single CVF for example can replace a large number of fixed filters or a grating based monochromator in an instrument. It is possible to adjust the center or edge wavelength by sliding the filter or rotating it.

CVFs are also ideally suited for order sorting in diode-array-based spectrometers.

We hope to see you at Photonics West

Optical filters for Covid-19 tester developed and delivered in ten days

A Danish technology firm is converting a medical apparatus to enable it to test for coronavirus.

In fourteen days, the Danish medical device producer Qlife modified its transportable analysis instrument so that it can test for SARS-CoV-2 in around 20 minutes.

By Bjørn Godske

bg@ing.dk

In record time, medical device producer Qlife has shown that a test for SARS-CoV-2 – the virus that causes the disease Covid-19 – can be integrated in their platform Egoo.Health. The testing device Egoo was developed to be able to test for a long list of bio-markers, but when the coronavirus outbreak gathered pace, management decided to act quickly. Ebbe Finding, who is Chief Technology Officer and co-founder of Qlife, explains:

“We already had plans to add a test for viruses to Egoo in the future, but with the current situation we went full steam ahead with developing it.”

Along with the Egoo.Health digital platform, the Egoo device has been in development for several years for the testing for a number of different bio-markers as a so-called Point-of-Care instrument – i.e. a device that can be physically moved to the patient in a hospital or to the general practitioner’s surgery.

In the longer term, it will be something the individual patient can have at home, just like many have their own blood pressure monitors at home today. Qlife became a listed company earlier this year, and the plan is to launch Egoo.Health for the testing of a number of bio-markers, for example, phenylalanine, haemoglobin, CRP (inflammation), ALAT (liver marker) etc.

Test integrated in platform

In the early stages of the current outbreak of the virus, the management in Qlife decided to try and add a test for the new virus to Egoo:

“With the outbreak of SARS-CoV-2, we rapidly got underway with testing it for the Egoo platform. The first step was to enter into an agreement with the Finnish company Aidian Oy on using their patented SIBA technology,” explains Ebbe Finding.

Therefore, the principle behind Egoo is also slightly different to that of the tried and tested RT-PCR method (Reverse Transcription Polymerase Chain Reaction), which is widely used in hospitals. The test time here is around four to six hours, and it must be conducted in a certified laboratory.

With the Finnish technology and the device from Qlife, the advanced laboratory equipment has been replaced by a process in which the sample, taken from the patient’s throat, can be tested at a constant temperature and thus does not need to undergo an advanced heating and cooling cycle, as is required in the case of RT-PCR:

“In practice, the patient takes a sample of saliva from their throat, the sample is put into a solution that releases the virus’s RNA, after which the solution is transferred to a capsule. The capsule is placed in Egoo, and after approximately 20 minutes, it is measured and the result is calculated and presented on a computer screen,” explains Ebbe Finding.

Optical filters developed and delivered in ten days

Central to Egoo are the optical filters that have to determine whether SARS-CoV-2 is present in the sample. A specific element of the virus’s RNA strand has been amplified, and a fluorescent molecule attaches itself to each new strand. This means that the sample is illuminated by light of a specific wavelength, the light is absorbed, and the fluorescent molecule begins to emit light of a longer wavelength. The more light is emitted from the fluorescent molecule, the greater the number of amplified strands. Here, it is important that the light that illuminates the sample, and the light from the fluorescent molecule are strictly separated so that the photodiode does not measure the light from the light source, but only the light from the fluorescent molecules.

Therefore, Qlife contacted Delta Optical Thin Film A/S, who have specialised in developing and producing optical filters for a long list of applications, for example, fluorescent microscopes and also Qlife’s Egoo. Here, everything else was put aside and an intensive development process was embarked upon. In just ten days, the team succeeded in developing, producing and testing the necessary filters.

“With our coating technology, that has been in development since the 1970s, we are able to let a single wavelength through, while we dim others by a factor of between 100,000 and a million times,” explains the company’s CTO, Henrik Fabricus.

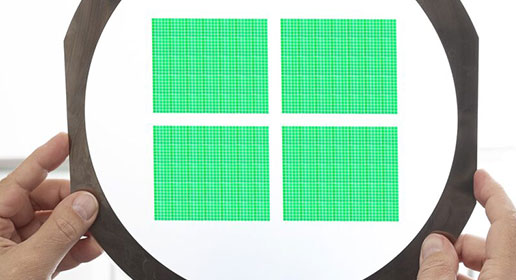

With optical filters, the art is to add hundreds of dielectric layers with different refractive indices, and with extreme accuracy. The light filtering function is triggered in the event of interference between the inter-reflected light waves. In the present case, three different filters had to be used, and the team succeeded in getting them all right on the first attempt. Thereafter, the filters had to be cut out so that they can fit into small devices, such as Egoo. In the present case, the filters only measure 4×4 mm², but Delta Optical Thin Film is also able to manufacture filters that are even smaller.

Same price as a mobile phone

The next step in the development of Egoo for testing for SARS-coV-2 will be a standardised test at North Zealand Hospital. It is expected to get underway at the end of April, after which Ebbe Finding expects that patient samples that have already been collected will be tested to verify the results:

“Thereafter, we shall have capsules with reagents manufactured, and production of the Egoo device will be upscaled. When we can have the system in use in the hospitals depends on the validations we will be carrying out within the next four to six weeks. After that, we will decide what happens next,” he says.

Ebbe Finding estimates that the price of Egoo for testing for SARS-CoV-2 will be around the price level for a mobile phone – without revealing which one.

More reading

Read more about the instrument and test at https://www.egoo.health and https://www.egoo.health/sars-cov-2.

We are rewarded with the "Potential 150"

Delta Optical Thin Film is rewarded with the ”Potential 150” award from Danske Bank. A reward dedicated to companies that inspires and makes a special difference.

Delta Optical Thin Film is rewarded with the ”Potential 150” award from Danske Bank. A reward dedicated to companies that inspires and makes a special difference.

As a justification for the award, Danske Bank emphasize our continues focus on sustainability which Danske Bank believed should act as a great source of inspiration for other companies.

Danske Bank put special attention on the construction process of our new headquarter where our focus on sustainability meant choosing a lot of “green” solutions not being the cheapest.

In addition, they also emphasize the way our products improve the quality of life for people bringing advanced optics into their everyday lives. For example, in the field of medical diagnostics.

We are honored to receive this award.

Delta Optical Thin Film A/S is moving into new facilities

Following strong growth Delta Optical Thin Film A/S is moving into its new purpose-built facilities in DTU Science Park in Hørsholm, Denmark. A new, larger facility became necessary as Delta Optical Thin Film A/S had outgrown its previous residence both in terms of production and office space. At the same time, the new manufacturing building offers a much cleaner production environment.

Delta Optical Thin Film A/S is moving into the new premises and simultaneously expanding its production capacity with new magnetron sputtering coaters, a new improved clean room, a completely new automatic ultrasonic cleaning line, and new dicing equipment. Together these investments will not only increase the production capacity but also create a cleaner production environment allowing for higher quality products.

The new building is custom designed to accommodate the very particular needs of manufacturing high-performance optical filters. The two-storey building will allow further considerable growth. Its roof is fully covered with solar panels that will make a sustainable contribution to our energy consumption. Our new automated ultrasonic cleaning line is completely alcohol-free and allows for the best possible cleaning result without discharging any harmful wastewater. It adheres to Danish environmental protection laws that are among the strictest worldwide.

Since Delta Optical Thin Film A/S was incorporated in December 2014, the company has experienced a doubling of its revenue. This was achieved by expansion of its customer base, expansion into new territories and new applications such as hyperspectral imaging or laser scanning microscopy. This growth was enabled by investments into new coating machines and technologies.

About Delta Optical Thin Film

Delta Optical Thin Film is the leading supplier of advanced, high-performance continuously variable filters commonly used in a variety of biomedical imaging applications including laser scanning microscopy, hyperspectral imaging, compact spectrometers, fluorescence microscopy, monochromators, and micro-plate readers among others.

Delta Optical Thin Film also provides single, multiband, laser-line and broadband band pass filters, long pass filters, short pass filters, dichroic and polarizing beam splitters along with other custom coated optical components. All filters can be delivered in different shapes and sizes down to tiny filters for Point-of-Care (PoC) instruments, fully tested – both spectrally and visually – with dedicated equipment.

Delta Optical Thin Film offers a wide range of high efficiency durable hard coated filters that have set the standard for high performance and precise operation. With its unique design tools and decades of experience, Delta can provide highly competitive standard filters and customised filters and optical components to exacting customer specific applications.

We look forward to seeing you at our new address Fremtidsvej 1, 2970 Hørsholm, Denmark or at one of the next events!

OSA Industry Member Profile - Delta Optical Thin Film

By Samantha Hornback, Research & Program Development Coordinator, The Optical Society

OSA Industry Development Associates (OIDA) member Delta Optical Thin Film, Denmark, is the leading continuously variable filter manufacturer in the industry. Calling themselves “The Optical Filter Company,” Delta puts an emphasis on customization and the highest quality products. To learn more about Delta and what it’s up to now, OSA spoke with CEO Poul Svensgaard, CTO Henrik Fabricius and Director of Sales and Marketing Oliver Pust. What follows is an edited version of that conversation.

Tell me about your company and its primary market.

Delta Optical Thin Film develops and manufactures high quality components in high volumes for instrument builders like microscope vendors, manufacturers of microplate readers and other types of optical instrumentation that use optical interference filters, dichroics and beamsplitters. This is the founding idea of the company. Over the years, we have developed technology that allows us to control all aspects of design and manufacture of our components, while keeping prices low. Our history goes back to the 1970s, when the focus was mostly on interference filters for fluorescence microscopes. Today, we have a new focus on continuously variable filters in addition to the homogeneous ones we were founded upon.

Quite often, our clients are very skilled optical engineers, but they may not be aware of all the facets of integrating optical filters into an optical measurement chain. We can often assist and add value by simplifying an optical system. Clients requesting a very advanced optical filter sometimes submit drawings that are far too complicated. We can take that and make it feasible. Working very closely with clients’ development engineering teams is definitely a key to our success.

We are able to offer so much customization due to our own design and optical monitoring software (OMS). Not only can we design the filters, but we can also design and manufacture the tools needed to make those filters. This technology also enables us to make continuously variable filters, something commercially available coating machines simply cannot do. The area of proprietary software has been leading the way as an enabling technology for creating advanced filters at competitive prices.

What goals drive Delta?

We are very much focused on bringing benefit to the people of the globe and trying to make products that have an impact on people’s daily lives. Our goal is to sustain our business and continue its growth. It’s critical for us to stay competitive, to make sure that we are still a viable supplier and that we are able to drive innovation for our clients.

We work frequently in medical diagnostics, new medicines, drug discovery, food quality and, more recently, point-of-care instruments. We deliver small, inexpensive minifilters for point-of-care instruments, some of which can be used at home. Of course, in the current situation, there is growing interest and need for point-of-care instruments, particularly those that can deliver the results quickly. The interesting thing is that these kinds of applications are just as advanced as the big lab equipment used today. Automation drives the cost reduction for these complex, yet small, components.

Beyond these types of applications, we have been expanding into the semiconductor industry, hyperspectral imaging and many others. Recently, we even received a request from NASA.

One other aspect that we find incredibly important is sustainability, not only for our employees, but for our customers as well. As a Danish company, we are already very fortunate that more than 50% of the country’s energy comes from wind turbines. At Delta, our new facility’s whole roof will be covered by solar panels, and we continually work toward being completely green. We don’t use any substances that cannot be directly poured into the sewer except for the oil for our vacuum pumps, and the water we use to clean our glasses before coating can be completely discharged without further cleaning. We as individuals strive to live sustainably, and we look after our employees and customers equally.

Where do you expect the company to be in 10 years?

We can tell you that we have been growing and almost doubling our profits in the last five years, and we expect similar growth to continue, especially within the medical market. From our own internal point of view, we are currently building a new facility that the whole company will move into this August. Based on trends in the industry, our new building will have greatly updated clean-room facilities, and we have expanded our capacity by acquiring new coating technology and sputtering machines. This will be a completely customized building, and the opportunities are very exciting.

We’ve talked a lot about how you work with your customers to make exactly what they need. How does your relationship with the customers influence your business?

We are a company that focuses on specific customers—original equipment manufacturers (OEMs). We are not a catalogue company where we have a plethora of filters that a customer can choose from. The relationship is best if we can get a deep insight into what our customers really need, not necessarily what they say or write down as specifications of what they want to have. It’s really a dialogue with the customer from the start.

What is the best decision that Delta has made?

We all agree that the best decision Delta has made was to become our own company. This happened five and a half years ago, and it was the right thing for us. Previously, the company was held by a public research institute that was a self-owned entity, almost like a foundation. That was acceptable initially for moving the technology out of the university level, but converting to a 100% commercial company has been critical to our success. This, coupled with Henrik’s development of high-performance continuously variable filters, created the foundation of our success.

Describe your career paths. What brought you all to where you are today?

Henrik and Poul both studied at the Technical University of Denmark. After completing his degree as M.Sc., Henrik went on earning a diploma as industrial researcher from the Academy of Technical Sciences and he worked on a number of different national research projects within optics. This made him receive the annual award of the Danish Optical Society in 1995 for his research in and realization of quasi inhomogeneous optical filters. His research and development of new optical coating techniques and technology for more than 30 years makes him a key stakeholder and enabler. Poul brings to Delta a more commercial focus. His career has mainly been with Danish companies, previously in acoustics and electronics. He joined Delta in 2008 and has focused on improving the customer experience and new technology. Oliver has a strong technical background as well. Before Delta, Oliver obtained a Ph.D. in laser optical measurement technology and worked in sales and product marketing. The opportunity to explore filters presented itself, and he made the switch.

Why did you decide to join OIDA, and what do you see as the value of that membership?

As a long-time individual member of OSA, Henrik advised the company that an OIDA membership would prove beneficial. We find that OIDA is an excellent platform with a good combination of all the scientific background but with an industrial reach that enables us to identify potential users of our technology. The recent webinars have been particularly valuable in times like these. Further, the workshops, market reports and the growing global outreach have helped our business greatly.

Delta Optical Thin Film A/S helps develop Covid-19 quick tests

We are extremely happy to have developed and produced a set of high-performance fluorescence filters for Danish Qlife to be used in their ground-breaking egoo.health Point of Care instrument. Qlife has licensed and implemented a test for Covid-19 that delivers a result within 20 minutes. Read more about the instrument and test at https://www.egoo.health and https://www.egoo.health/sars-cov-2.

You can also read Greg Blackman‘s recent feature about optical fluorescence filters for Covid-19 testing in Electro Optics magazine.

We Are Open for Business, Set up a Teams Meeting!

#covid19 and its possible implications make the headlines these days. At Delta Optical Thin Film A/S we want to minimise the risks associated with the pandemic for our customers, suppliers and ourselves.

Therefore, we decided to cease all travel activities until further notice. But you can still meet, see and talk to us virtually. We use Microsoft Teams to easily set up calls, video conferences and share documents.

You can even use it in your browser without installing any software. Just call at +45 70 70 71 46 or send us an email to request an online meeting with our experts!

Fight Corona!

Delta Optical Thin Film A/S launches 4G Continuously Variable Filters

Delta Optical Thin Film has utilised its decades of experience to develop the 4th generation Continuously Variable Short Wave Pass and Continuously Variable Long Wave Pass Filters.

A continuously variable filter is a wedged filter that has spectral properties that vary continuously along one dimension of the filter. Just one of these filters can be used as an alternative to several fixed filters in an instrument, and the centre or edge wavelength can be adjusted by sliding the optical filter.

All continuously variable filters from Delta Optical Thin Film are coated with ultra-hard surface coatings, which are produced with an advanced plasma process that builds layers with a much higher packing density than traditional hard coatings. These optical filters set new standards in edge steepness and transmission level, and also provide improved blocking. Coated on a single fused silica substrate, these Continuously Variable Filters exhibit minimal auto-fluorescence and a high threshold to laser damage.

The combination of continuously variable long wave pass filters (CVLWP) and continuously variable short wave pass filters (CVSWP) enables the construction of bandpass filters, which can be tuned continuously between 410 nm and 895 nm. These filters also have the advantage of tunable bandwidth. The total wavelength range is split into two sets of CVFs: two CVLWP and two corresponding CVSWP. The physical length is longer than for the 3G CVF. This yields a higher spectral resolution with the same light spot. The blocking level (OD value) has increased, and the blocking range of the CVLWPs has been extended to 1025 nm. This removes the needs for additional blocking filters.

The four new filters are:

- 4G CVLWP 410 nm – 652 nm, 82.4x13x0.9 mm³, LF104160

- 4G CVSWP 425 nm – 652 nm, 82.4x13x0.9 mm³, LF104161

- 4G CVLWP 652 nm – 895 nm, 82.4x13x0.9 mm³, LF104162

- 4G CVSWP 652 nm – 895 nm, 82.4x13x0.9 mm³, LF104163

Please contact us at sales@deltaopticalthinfilm.com for more information and pricing.